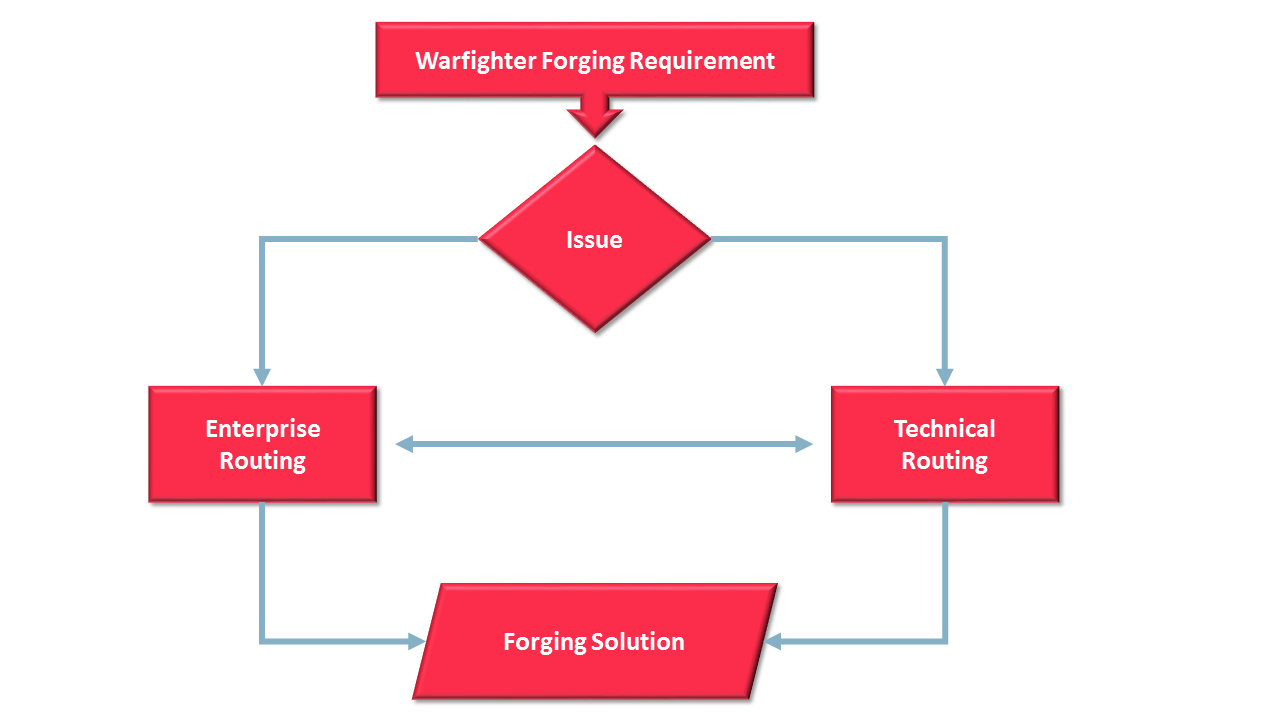

Improved Die Lubrication – Forging Billet

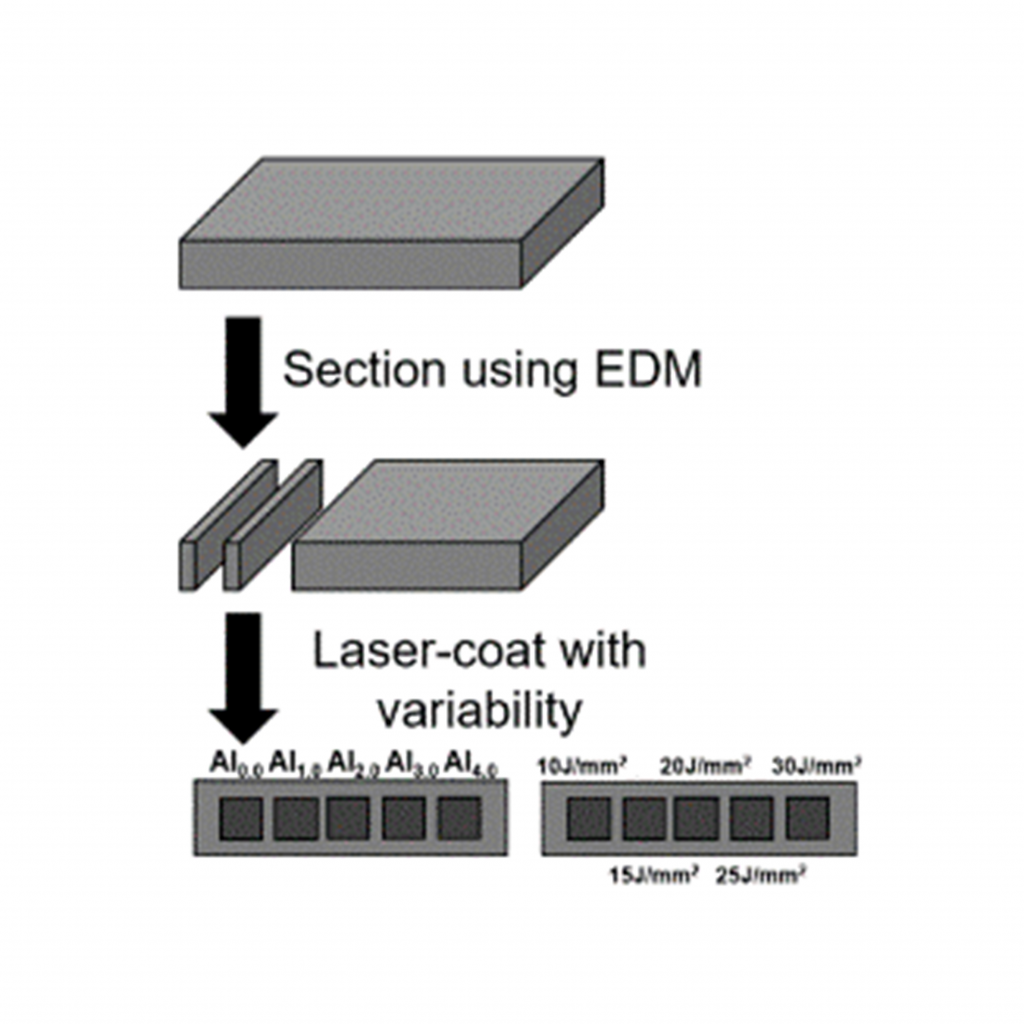

Aluminum-based coatings have proven very effective in preventing decarburization, but compromised the surface of the steel. The coating needs to act as a barrier; it should not bond or react with the steel. The team envisions the use of automation and robotics to reduce the cost of application, improve cycle times, and to provide additional safety to the operator.

Project: Evaluation of Oxidation-Resistant Coatings – IFT program

Objective:

Evaluate protective coatings for forging billets to prevent the oxidation and decarburization that occurs during pre-heating and develop a cost- effective and efficient application method for applying them.

Solution:

Leverage the initial findings of the FIERF study to conduct a more detailed evaluation of commercially available coatings. A truly innovative result of this project would be to identify an effective application method.

Principal Investigators: