Improved Die Lubrication – Forging Die

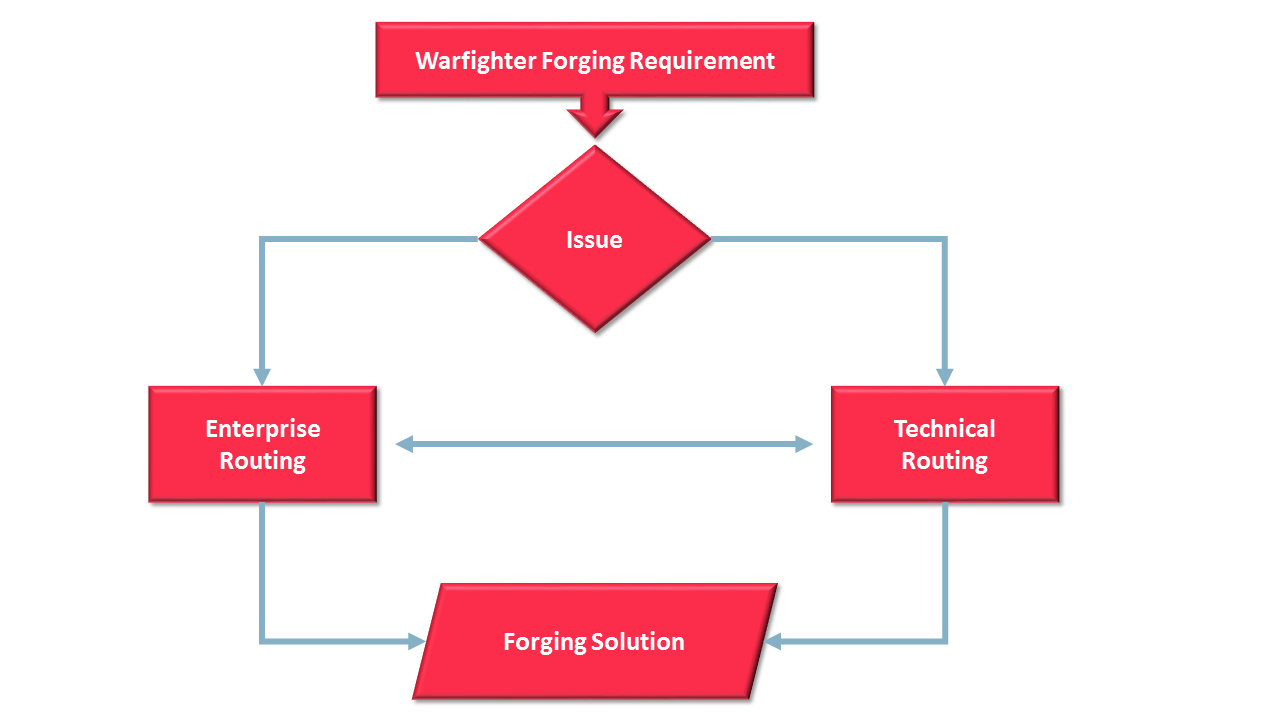

Lubricants are applied to the faces of forging dies to reduce friction between the die and the workpiece, help metal fill the die cavity, and prevent metal build-up on the die surface. Prior results revealed significant potential for coatings and/or surface modification to reduce friction in forging processes.

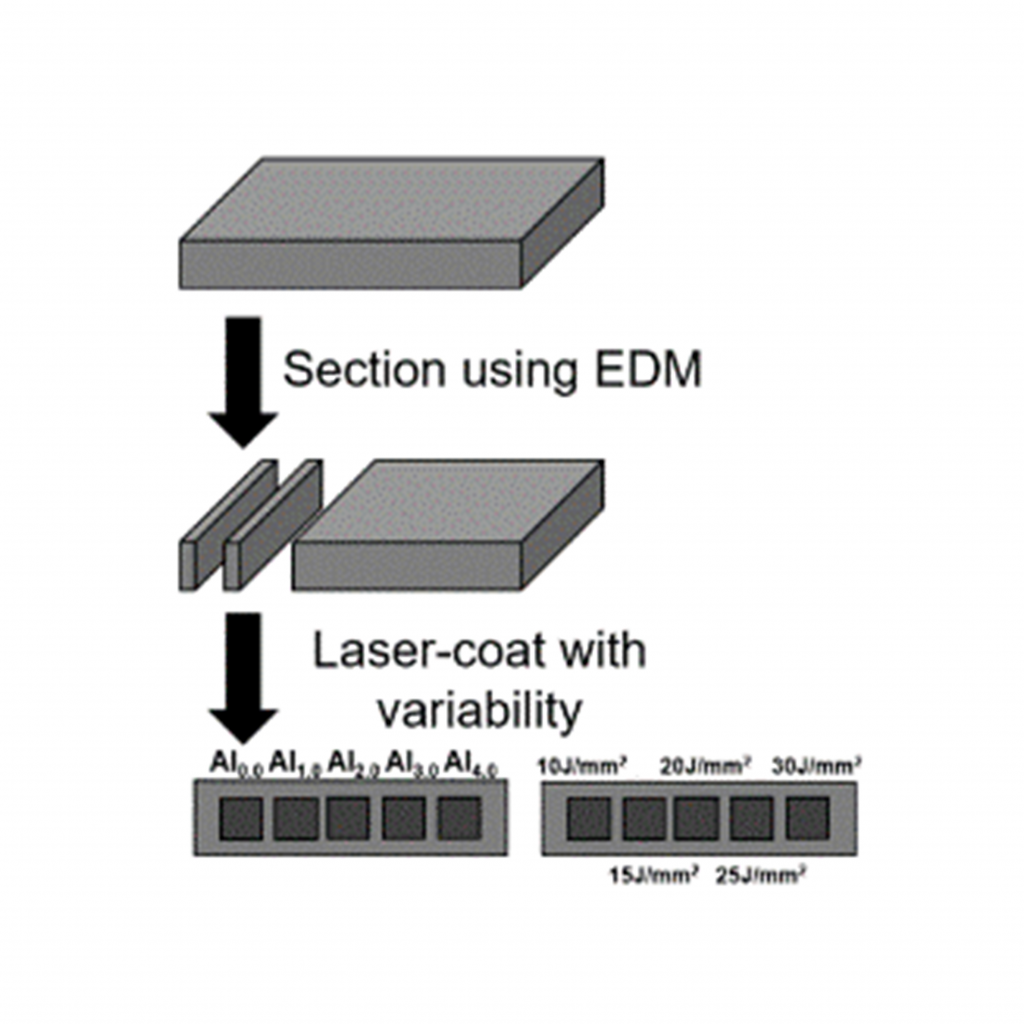

Project: Evaluation of Permanent Coatings and Surface Texturing – IFT program

Objective:

Examine coatings techniques and methods to modify the surface topography to identify optimum surface conditions to reduce or eliminate the need for conventional lubricants.

Solution:

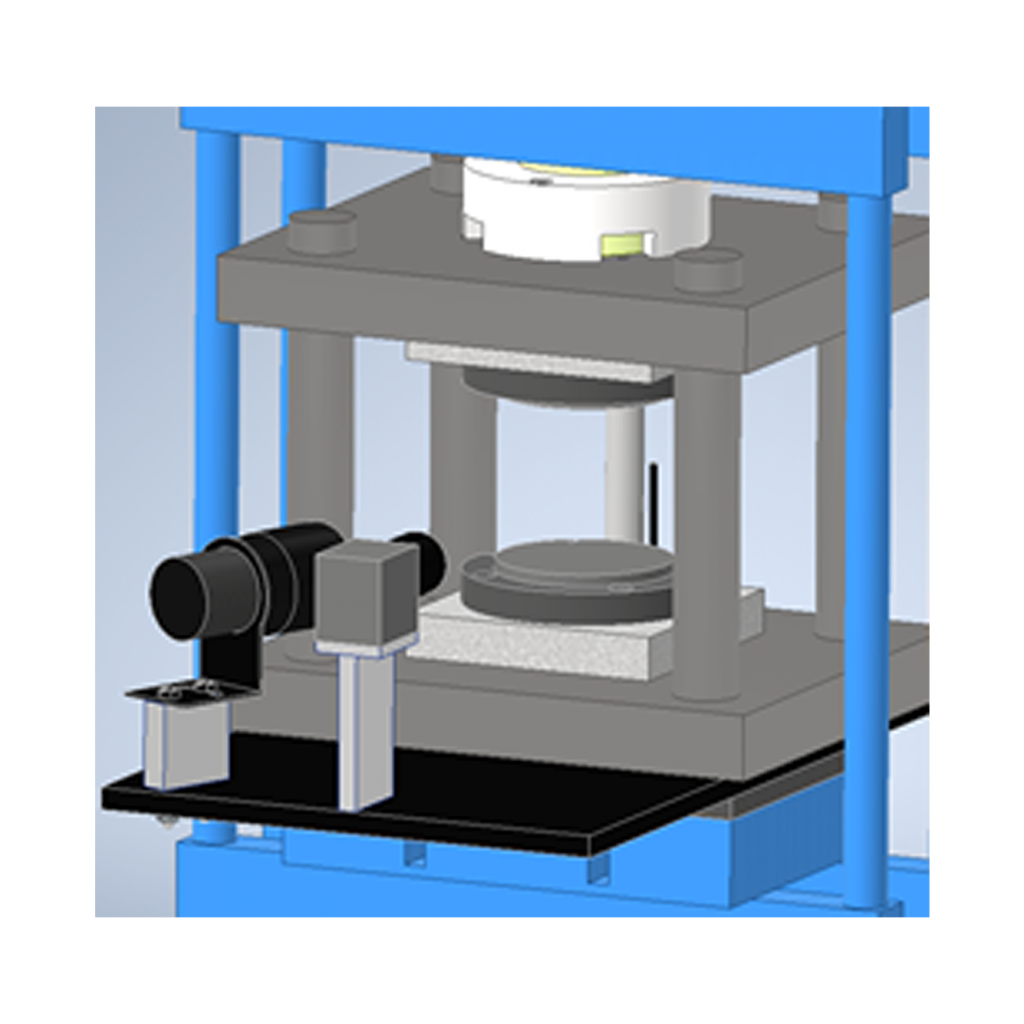

Evaluate the friction performance of the coatings and surface texturing, perform a detailed examination of the chemical, microstructural and performance characteristics of the coatings. Optimize and test the coatings both in the laboratory and at commercial forging shops.

Principal Investigator on Both Projects: